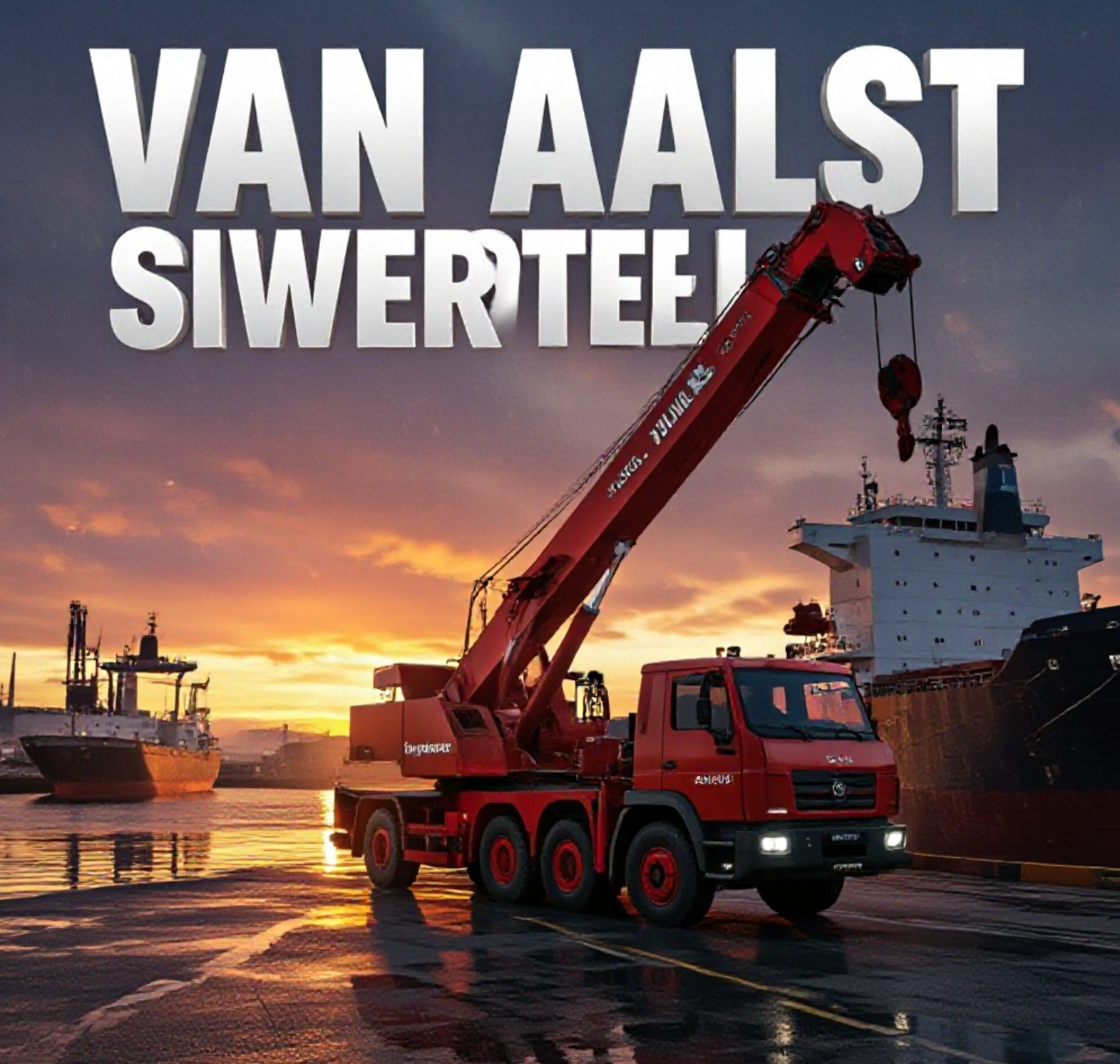

A brand-new era of cement handling just began at the Port of Dundee. On 19 February 2026, Dutch specialist Van Aalst Bulk Handling handed over a state-of-the-art mobile pneumatic ship unloader to Nova Cement Scotland, promising faster, cleaner, and greener unloading for the country’s growing construction sector.

The high-capacity machine is already on site and undergoing final commissioning, ready to slash discharge times and virtually eliminate dust emissions.

What Makes This Unloader Special

The new unit is a Van Aalst Siwertell 5000 S road-mobile pneumatic ship unloader, capable of handling up to 500 tonnes of cement per hour from vessels up to 40,000 DWT.

Unlike traditional grab cranes that spill dust and damage product, this machine uses enclosed vacuum technology. Cement flows through sealed pipes from ship to silo with almost zero emissions, a huge win for both workers and nearby communities.

The system is fully mobile. It drives on its own wheels straight to the quay, connects in minutes, and starts working. No fixed infrastructure needed.

Why Nova Cement Scotland Needed It Now

Scotland’s construction boom shows no signs of slowing. Housing, wind-farm bases, roads, and rail projects all hunger for cement.

Nova Cement Scotland, a joint venture backed by Irish and Scandinavian investors, opened its £28 million import terminal in Dundee in late 2025. The facility supplies low-carbon cement blends across central and northern Scotland.

Before this unloader arrived, the terminal relied on smaller rented units and occasional crane operations. Turnaround times stretched, costs climbed, and dust complaints from residents increased.

The new Van Aalst machine cuts vessel discharge time by up to 60 percent and brings dust levels close to zero. Terminal manager Callum Reid called it “the single biggest upgrade we could make.”

Inside the Delivery Day

Van Aalst’s commissioning team arrived before sunrise on 19 February. By noon the unloader was positioned under the first test hatch of a 15,000-tonne vessel carrying Irish clinker.

Operators ran calibration cycles, fine-tuned the filter systems, and trained Nova staff on the touchscreen controls. Everything went smoothly.

“It’s rare to see a handover this clean,” said Van Aalst project leader Mark de Boer. “The crew here knows cement inside out. They asked all the right questions from day one.”

Bigger Picture for Scottish Industry

This delivery matters beyond one terminal.

Scotland aims to cut embodied carbon in construction by 50 percent by 2030. Efficient, low-dust unloading protects both the environment and the reputation of cement imports at a time when communities scrutinise every tonne that arrives.

The unloader also future-proofs the Dundee terminal. It can handle classic grey cement today and switch to low-carbon alternatives like limestone-calcined clay cement tomorrow without any modifications.

Several other UK ports are watching closely. Sources tell us two east-coast terminals have already opened talks with Van Aalst for similar units in 2026-2027.

Nova Cement Scotland plans to run the machine around the clock during peak season. That single unloader could move more than 800,000 tonnes a year, enough to supply roughly 40 percent of Scotland’s current cement demand.

As the sun set over the Tay on 19 February, the bright red Van Aalst machine stood ready under floodlights, hose already connected to its first ship. A quiet, almost humble moment, yet one that will help build thousands of Scottish homes, schools, and renewable projects for years to come.

What do you think: is this the kind of clean, efficient technology our ports need more of? Drop your thoughts below, and if you’re sharing on social, use #NovaCementScotland or #CleanCementUK.