West Fraser’s MDF and particleboard mill in Cowie, Scotland, has achieved a significant reduction in its electricity costs, thanks to a collaboration with Rockwell Automation. The partnership focused on improving energy efficiency, leading to an impressive annual savings of $266,000 for the mill.

Smart Energy Management

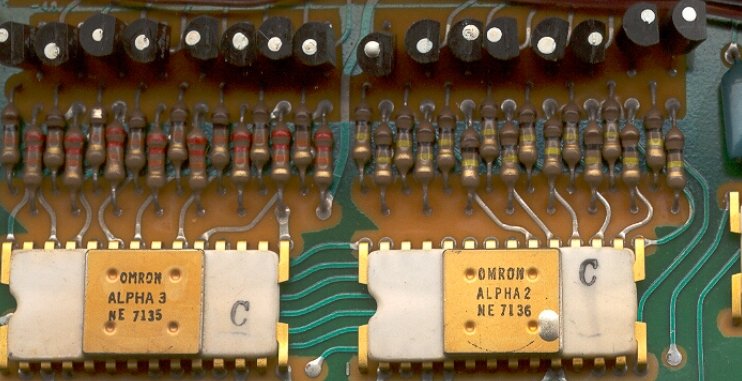

West Fraser’s mill implemented Rockwell Automation’s Intelligent Package Power (IPP) system, which integrates variable frequency drives (VFDs) to optimize energy consumption. The system targets energy-heavy equipment such as pumps, fans, conveyors, and compressors, reducing the drag that usually hampers efficiency.

One of the core components of the upgrade is Rockwell’s Centerline 1500 medium-voltage motor control center, coupled with three PowerFlex 6000T medium-voltage VFDs. These devices were installed across three energy-intensive fan applications at the mill, allowing for a reduction in motor speed by 25 percent. As a result, the energy consumption of the motors was reduced by around 60%, translating into substantial savings.

Real-Time Data Access for Better Decision-Making

A standout feature of the IPP system is its ability to provide real-time data on the performance of the mill’s equipment. By simplifying the integration between process and electrical systems, the system gives mill operators immediate access to critical data. This capability enables workers to make more informed and timely decisions about equipment operations, leading to optimized energy usage and further cost savings.

A Step Toward Sustainability

The energy savings of $266,000 highlight the positive financial and environmental impact of adopting advanced automation technology. By reducing energy consumption and improving operational efficiency, West Fraser not only cut costs but also took significant steps toward more sustainable practices at its Cowie mill.

This collaboration is a prime example of how smart automation solutions can drive significant energy and cost savings in industrial operations, promoting both economic and environmental benefits.